How Camm Memory Outperforms NAND Technology

How Camm Memory Outperforms NAND Technology in today’s hyperconnected digital era, data isn’t just a commodity—it’s currency. As the demand for faster, more resilient memory solutions grows exponentially, the market has been hunting for a breakthrough that balances raw speed, energy efficiency, and architectural innovation. Enter Camm Memory, a promising contender with the potential to dethrone legacy storage tech. The debate of Camm Memory vs NAND is no longer speculative—it’s becoming a defining conversation in the future of computing.

Understanding the Memory Hierarchy: Where NAND Falls Short

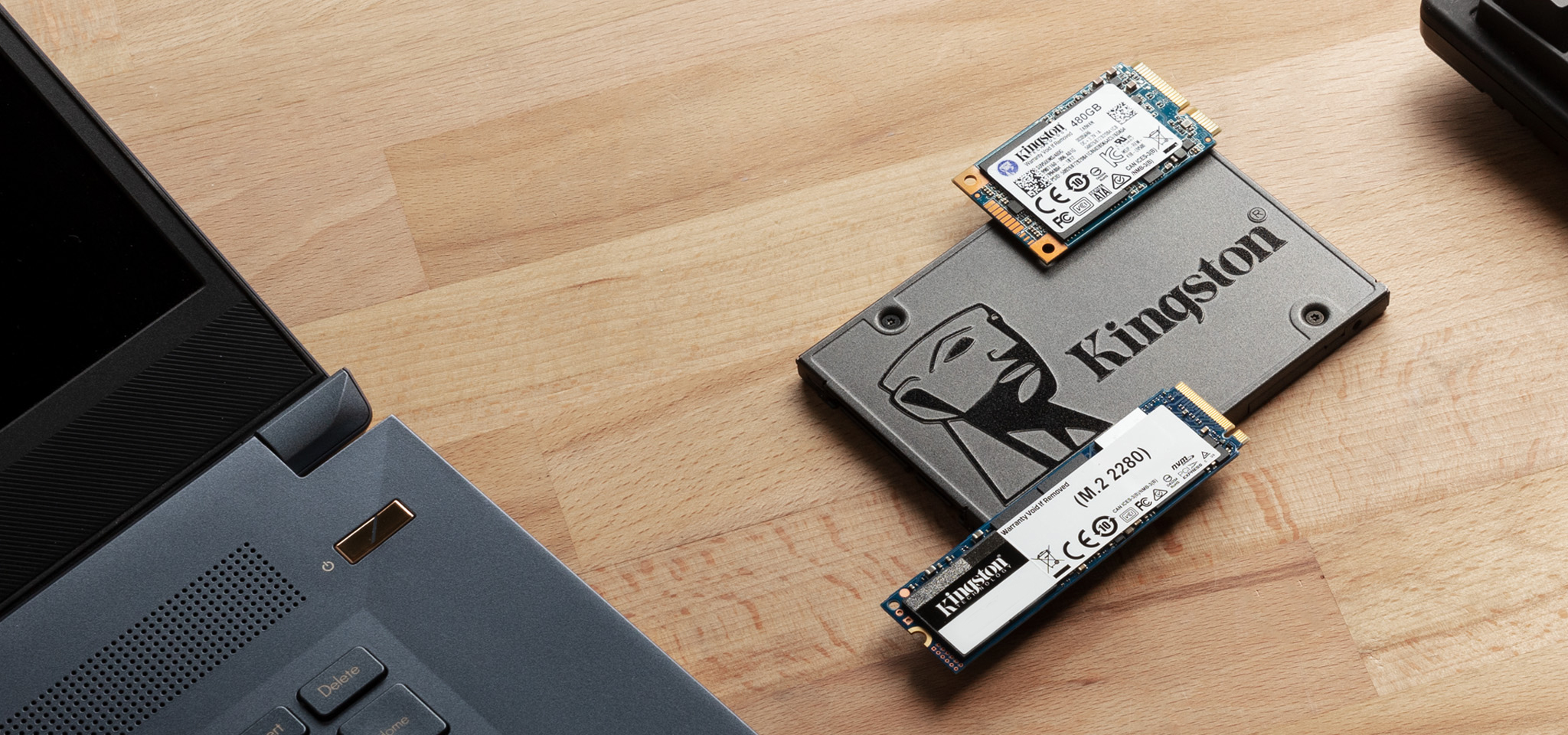

Before diving into Camm’s competitive edge, it’s essential to contextualize what NAND flash memory brings—and where it lags. NAND, the non-volatile storage technology found in solid-state drives (SSDs), USB flash drives, and smartphones, has long ruled the roost due to its affordability and density.

Yet, as systems grow more data-hungry, NAND’s inherent bottlenecks become glaring:

- Latency limitations during high-speed read/write operations.

- Endurance concerns in enterprise-scale environments.

- Interface restrictions, particularly with traditional serial protocols.

NAND’s cell degradation over time and the lag introduced during garbage collection cycles make it less ideal for next-gen real-time applications like autonomous vehicles or AI inferencing workloads.

The Rise of Camm Memory: Architectural Brilliance

Camm (Compression Attached Memory Module) is not just another tweak to existing hardware. It represents a reimagination of the memory form factor itself. Developed as a modern alternative to SO-DIMMs, Camm Memory compresses the vertical design inefficiencies seen in traditional modules and reorients them with sleek horizontal packaging. This structural revamp isn’t just aesthetic—it’s functional brilliance.

By reducing the physical height of memory modules, Camm enables:

- Better thermal dissipation,

- Tighter integration with compact form-factor systems,

- Shorter signal paths for faster data transfer.

When analyzing Camm Memory vs NAND, the architectural superiority is a foundational advantage. While NAND struggles with scaling in power-constrained and heat-sensitive environments, Camm thrives.

Speed: The Ultimate Differentiator

In the domain of raw speed, Camm Memory vs NAND isn’t even a fair fight.

NAND flash, though significantly faster than spinning hard drives, is still tethered to the limitations of its controller interfaces. Whether it’s SATA-based SSDs or even NVMe over PCIe 4.0, latency remains in the microsecond range.

Camm, designed to be used as a direct DRAM alternative, operates in nanoseconds.

The implications are massive:

- Boot times are slashed to a fraction.

- System responsiveness feels almost psychic.

- High-bandwidth computing tasks like 8K video editing or large-scale machine learning training experience minimal I/O friction.

When Camm modules are integrated directly with CPUs or GPUs, the bypass of intermediate buses further amplifies performance metrics. Real-time applications no longer need to compromise on latency.

Energy Efficiency and Sustainability

Another arena where Camm Memory vs NAND shows a sharp contrast is energy consumption. Camm’s unique layout and material usage allow for more efficient thermal dynamics. Lower heat means lower cooling requirements, reducing total power draw.

NAND, conversely, often suffers from thermal throttling under sustained workloads. Heat buildup not only deteriorates performance but accelerates wear cycles, leading to earlier component failure.

In energy-conscious data centers, deploying Camm can contribute to substantial reductions in:

- Cooling infrastructure costs,

- Power supply strain,

- Carbon footprint metrics.

With the increasing importance of ESG (Environmental, Social, and Governance) goals in tech procurement, the adoption of greener memory solutions is no longer a choice but a mandate.

Durability: Designed for Longevity

Camm modules exhibit superior endurance by leveraging advanced signal integrity techniques and lower write amplification. In contrast, NAND, particularly TLC (Triple-Level Cell) and QLC (Quad-Level Cell) variants, inherently degrade over time due to the finite number of program/erase cycles.

In enterprise-grade environments like cloud hyperscalers or real-time data lakes, NAND needs elaborate wear-leveling algorithms and over-provisioning buffers to sustain throughput. Camm, on the other hand, avoids these pitfalls with a more DRAM-aligned operation model that doesn’t rely on flash-based storage wearouts.

When comparing Camm Memory vs NAND, this means:

- Less downtime,

- Longer MTBF (Mean Time Between Failures),

- Predictable maintenance schedules.

Flexibility Across Verticals

While NAND is typically pigeonholed into consumer electronics and mid-tier SSDs, Camm’s versatility opens doors across multiple industry verticals. From aerospace systems requiring ruggedized, low-profile memory to edge computing devices deployed in smart cities, Camm’s modular adaptability makes it an attractive choice.

Consider these emerging use cases:

- Autonomous Vehicles: Faster sensor data processing.

- Medical Imaging: Near-instantaneous data reconstruction.

- IoT Gateways: Compact design with powerful memory access.

- Quantum Simulations: High-bandwidth, low-latency matrix operations.

In every scenario where performance, thermals, and durability converge, Camm stakes a serious claim over NAND.

Cost Considerations: Breaking the Price Myth

Critics of Camm often raise one flag—cost. NAND has benefited from decades of mass production, enabling per-gigabyte prices that are hard to beat. However, this gap is closing. As economies of scale favor Camm and fabrication processes mature, the price premium is shrinking.

Moreover, when evaluating Camm Memory vs NAND, total cost of ownership (TCO) tells a different story:

- Camm requires fewer cooling peripherals.

- Lower failure rates reduce replacement cycles.

- Superior performance cuts down on processing delays and electricity usage.

What initially seems like a higher upfront investment soon proves fiscally prudent in the long term.

Reliability in Extreme Environments

NAND’s Achilles’ heel is its susceptibility to bit rot, thermal instability, and susceptibility to radiation in extreme conditions. Camm, by virtue of its denser, more robust form factor, offers enhanced protection against these variables.

For aerospace, defense, or deep-sea deployment, Camm modules can be:

- Hermetically sealed for zero-atmosphere operation,

- Reinforced for shock and vibration resistance,

- Calibrated for wide temperature ranges (-40°C to 125°C).

Such resilience ensures that when mission-critical systems demand bulletproof memory performance, Camm delivers.

Future-Proofing: A Platform for Innovation

When tech companies make hardware decisions, they aren’t just solving today’s problems—they’re betting on tomorrow’s standards. In the Camm Memory vs NAND discourse, Camm emerges as the more future-ready architecture.

Here’s why:

- It aligns with emerging bus standards like PCIe 6.0 and CXL.

- It supports stacking mechanisms for 3D memory integration.

- It’s modular enough to work in AI accelerators, AR/VR rigs, and quantum computing environments.

With data requirements ballooning across all sectors, relying on NAND’s traditional latency-prone, cell-fatigue-prone infrastructure seems like planning for obsolescence. Camm, by contrast, sets the foundation for evolvable systems.

Real-World Adoption: Signs of Momentum

Early adopters aren’t waiting. Leading manufacturers in gaming laptops and enterprise workstations have already begun shipping Camm-integrated devices. The gaming community, known for pushing hardware to its limits, has responded with enthusiasm to the gains in frame stability and faster load times.

Meanwhile, hyperscale data centers are trialing Camm in AI workloads—particularly LLM (large language model) training where every microsecond counts. In the Camm Memory vs NAND equation, use cases demanding velocity and reliability consistently lean toward Camm.

Software Ecosystem and Driver Support

Memory isn’t just hardware—it’s part of a symbiotic system. Compatibility, driver support, and software integration matter. Here, too, Camm shines. Its open-standard push has seen collaboration from industry groups and chipmakers to ensure broad support.

Operating systems are beginning to optimize for the module’s lower latency. Memory allocation algorithms can now leverage Camm’s bandwidth and structure more intelligently, improving overall system throughput.

While NAND still commands legacy compatibility, it’s rooted in architectures that struggle to scale with modern software demands.

The Verdict: Why Camm Triumphs

In the grand performance showdown of Camm Memory vs NAND, the winner is clear when evaluated on:

| Metric | Camm Memory | NAND |

|---|---|---|

| Latency | Nanoseconds | Microseconds |

| Durability | High | Medium to Low |

| Thermal Efficiency | Superior | Moderate |

| Speed | Exceptional | Moderate |

| Cost Efficiency (TCO) | Strong | Lower upfront only |

| Modularity | High | Low |

| Environmental Resilience | Excellent | Limited |

| Software Integration | Growing Rapidly | Legacy Support |

The trajectory of memory technology points toward compression, speed, efficiency, and durability—all traits Camm embodies.

The digital future doesn’t have time to wait. Applications demand immediacy. Devices expect minimal lag. Organizations need maximum uptime. Camm Memory vs NAND is more than a spec sheet comparison—it’s a philosophical divergence between legacy and next-generation thinking.

Camm Memory isn’t just outperforming NAND. It’s rewriting the rules of what memory can do. As the world marches deeper into AI-powered automation, edge-based intelligence, and immersive computing, the need for agile, resilient, and blisteringly fast memory solutions has never been clearer. And on that front, Camm isn’t just keeping pace—it’s taking the lead.